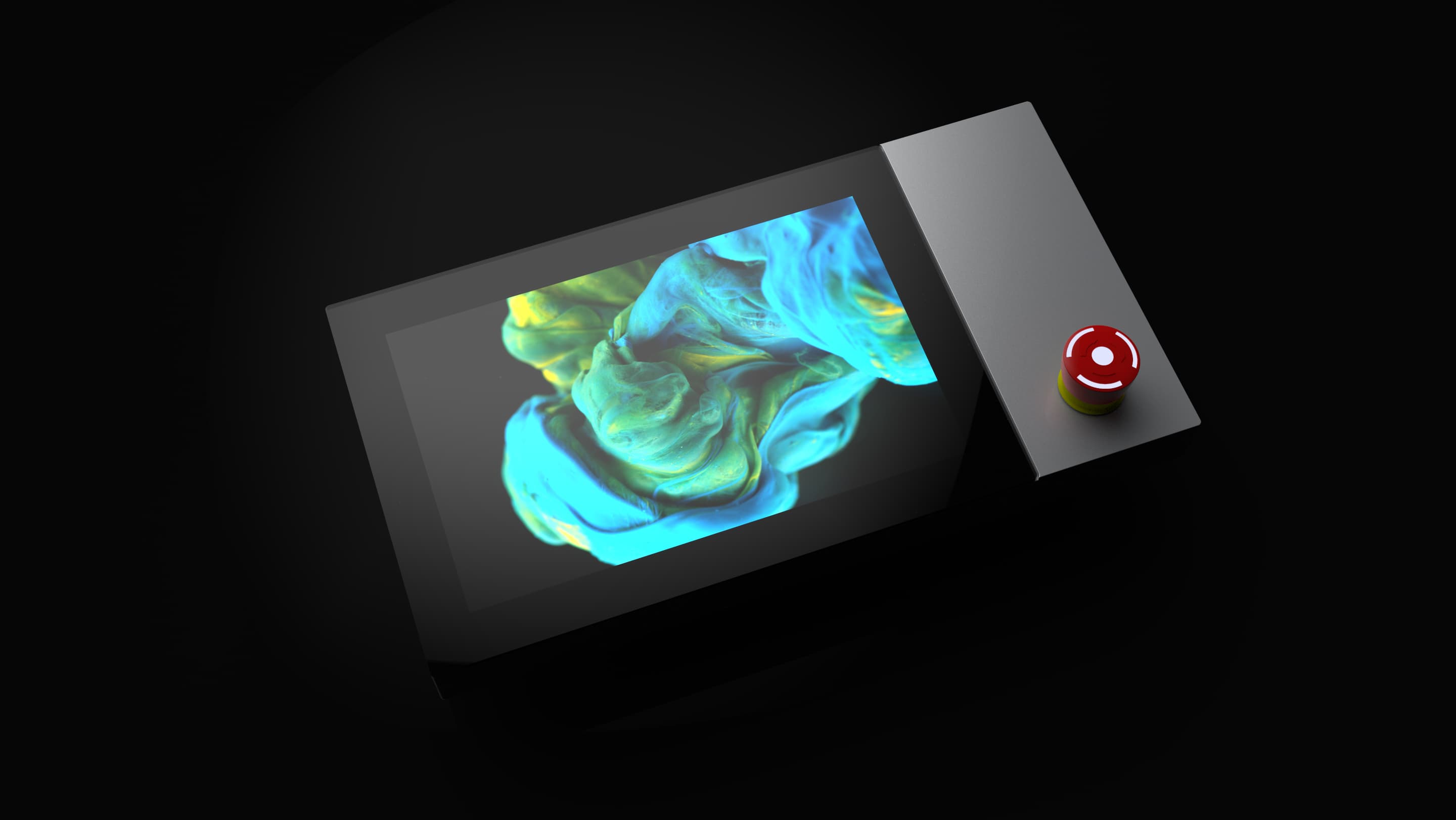

Human-Machine Interfaces (HMIs) have transformed how operators interact with industrial machinery, leading to increased efficiency, safety, and ease of use. As technology evolves, touch screen HMIs are becoming more advanced, promising to revolutionize industrial applications further. This blog post explores the current trends, future prospects, and the impact of touch screen HMIs on the industrial landscape.

The Evolution of Touch Screen HMIs

The journey of HMIs began with basic push-button interfaces and has progressed to sophisticated touch screens. Early HMIs were limited in functionality, often relying on physical buttons and switches to control machinery. These systems were cumbersome and required significant training to operate effectively.

The introduction of touch screen technology marked a significant milestone. Touch screens provided a more intuitive and user-friendly interface, allowing operators to interact with machines more naturally. Early touch screen HMIs were basic, but advancements in display technology, processing power, and software capabilities have led to highly interactive and responsive systems.

Current Trends in Touch Screen HMIs

Enhanced User Experience

Modern touch screen HMIs prioritize user experience. They feature high-resolution displays, multi-touch capabilities, and user-friendly interfaces. These improvements make it easier for operators to monitor and control machinery, reducing the likelihood of errors and improving overall efficiency.

Integration with IoT and Industry 4.0

The integration of HMIs with the Internet of Things (IoT) and Industry 4.0 technologies is another significant trend. Touch screen HMIs can now communicate with various sensors and devices, providing real-time data and analytics. This integration enables predictive maintenance, remote monitoring, and advanced data analysis, leading to smarter and more efficient industrial operations.

Customization and Flexibility

Modern HMIs offer extensive customization options, allowing companies to tailor the interface to their specific needs. This flexibility ensures that operators can access the information they need quickly and easily. Additionally, touch screen HMIs are designed to be adaptable, supporting various industrial applications and environments.

Enhanced Security Features

As industrial systems become more interconnected, security has become a critical concern. Touch screen HMIs now incorporate advanced security features, such as user authentication, encrypted communication, and secure boot processes. These measures help protect industrial systems from cyber threats and unauthorized access.

Future Prospects of Touch Screen HMIs

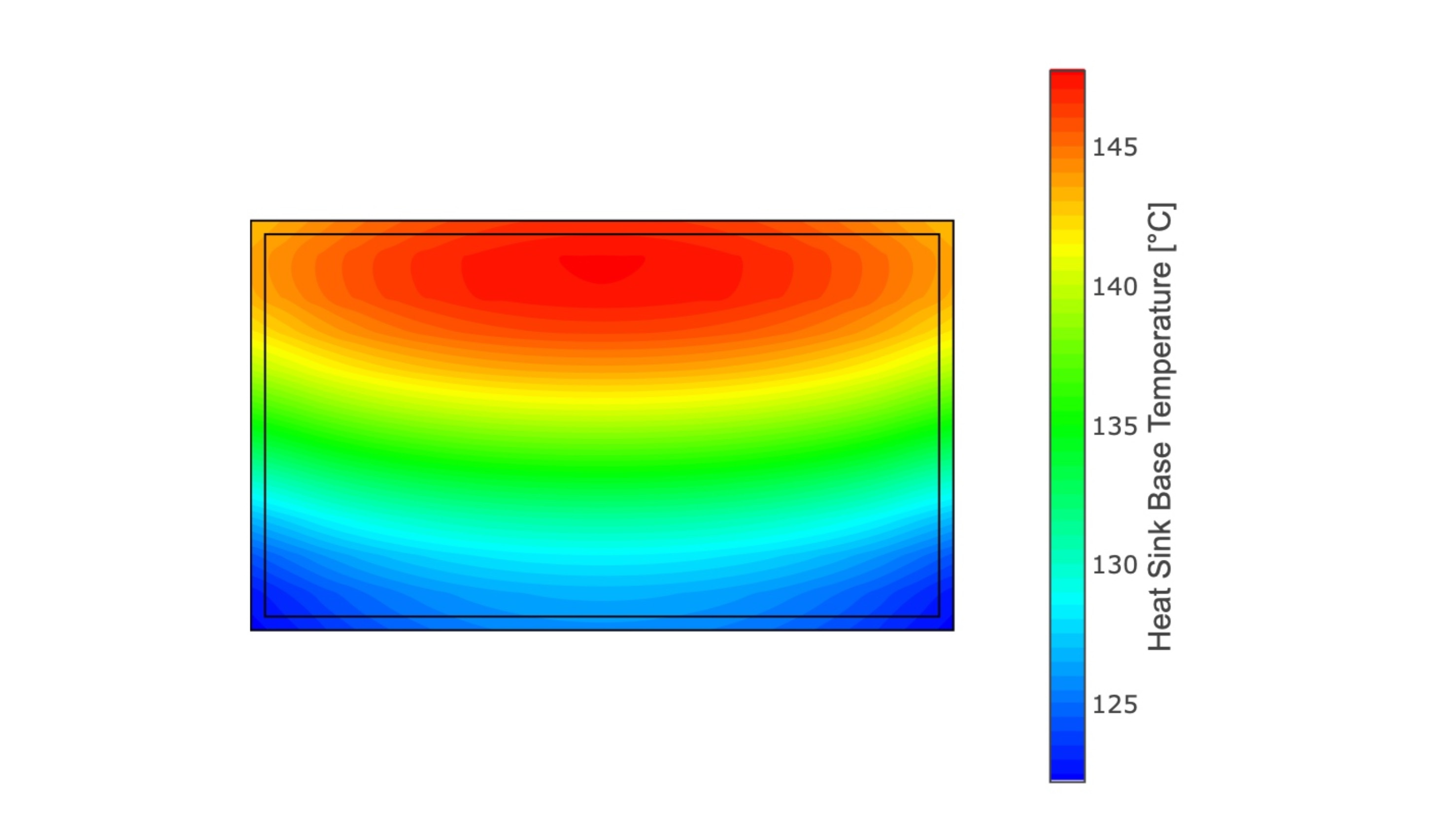

Advanced Visualization and Augmented Reality

One of the most exciting prospects for touch screen HMIs is the incorporation of advanced visualization techniques and augmented reality (AR). Future HMIs will likely feature 3D visualization, allowing operators to see detailed models of machinery and processes. AR can overlay critical information on the physical world, providing operators with real-time guidance and troubleshooting assistance.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are set to play a significant role in the future of touch screen HMIs. These technologies can analyze vast amounts of data to identify patterns and anomalies, providing operators with predictive insights and recommendations. AI-powered HMIs can adapt to individual operator preferences, improving usability and reducing the learning curve.

Gesture and Voice Control

The next generation of touch screen HMIs may incorporate gesture and voice control, providing operators with alternative ways to interact with machines. Gesture control allows operators to use hand movements to control machinery, reducing the need for physical contact with the screen. Voice control can enable hands-free operation, improving safety and efficiency in environments where operators need to use both hands for other tasks.

Wireless and Remote Capabilities

Wireless and remote capabilities are becoming increasingly important in industrial applications. Future touch screen HMIs will likely feature enhanced wireless connectivity, enabling operators to control and monitor machinery from a distance. This capability is particularly beneficial in hazardous environments where physical access to machinery may be dangerous.

Increased Durability and Environmental Resistance

As touch screen HMIs are used in various industrial environments, durability and resistance to harsh conditions are crucial. Future HMIs will likely be more rugged, with enhanced resistance to dust, water, extreme temperatures, and other environmental factors. This durability ensures reliable performance in demanding industrial settings.

The Impact of Touch Screen HMIs on Industrial Applications

Improved Efficiency and Productivity

Touch screen HMIs significantly improve efficiency and productivity in industrial applications. The intuitive interfaces reduce the time operators spend learning and navigating the system, allowing them to focus on their tasks. Real-time data and analytics enable quick decision-making, optimizing processes and reducing downtime.

Enhanced Safety and Ergonomics

Safety is a paramount concern in industrial environments. Touch screen HMIs contribute to safer operations by providing operators with critical information and alerts. The ergonomic design of touch screens reduces physical strain on operators, minimizing the risk of repetitive strain injuries.

Reduced Training Time

Traditional HMIs often required extensive training for operators to use effectively. The intuitive nature of touch screen interfaces reduces the training time needed, allowing new operators to become proficient more quickly. This reduction in training time translates to cost savings and faster onboarding of new personnel.

Better Data Management and Analytics

The integration of touch screen HMIs with IoT and data analytics platforms enhances data management capabilities. Operators can access detailed reports and real-time data, enabling better decision-making and process optimization. Advanced analytics can identify trends and predict potential issues, allowing for proactive maintenance and reducing unplanned downtime.

Scalability and Adaptability

Touch screen HMIs offer scalability and adaptability, making them suitable for various industrial applications. Whether used in a small manufacturing facility or a large-scale industrial plant, these HMIs can be customized to meet specific requirements. This scalability ensures that touch screen HMIs can grow with the business, accommodating new processes and technologies.

Challenges and Considerations

Cost and Implementation

While touch screen HMIs offer numerous benefits, the initial cost and implementation can be significant. Companies need to invest in new hardware, software, and training for operators. However, the long-term benefits often outweigh the initial investment, with improved efficiency and reduced downtime leading to cost savings.

Cybersecurity Concerns

As industrial systems become more connected, cybersecurity concerns are paramount. Touch screen HMIs must incorporate robust security measures to protect against cyber threats. Regular updates and maintenance are essential to ensure these systems remain secure.

Operator Acceptance

Introducing new technology can sometimes be met with resistance from operators accustomed to traditional systems. Ensuring operator acceptance requires effective training and demonstrating the benefits of the new HMIs. Engaging operators in the design and implementation process can also help increase acceptance and adoption.

Conclusion

The future of touch screen HMIs in industrial applications is promising, with advancements in technology driving significant improvements in efficiency, safety, and usability. As touch screen HMIs continue to evolve, they will play an increasingly vital role in the industrial landscape. By embracing these technologies, companies can unlock new levels of productivity and innovation, positioning themselves for success in the ever-changing industrial environment.

Touch screen HMIs are not just a trend but a transformative technology that will shape the future of industrial applications. As we look ahead, the integration of advanced visualization, AI, gesture and voice control, and enhanced connectivity will further enhance the capabilities of touch screen HMIs. The journey is just beginning, and the potential for these technologies to revolutionize industrial operations is immense.