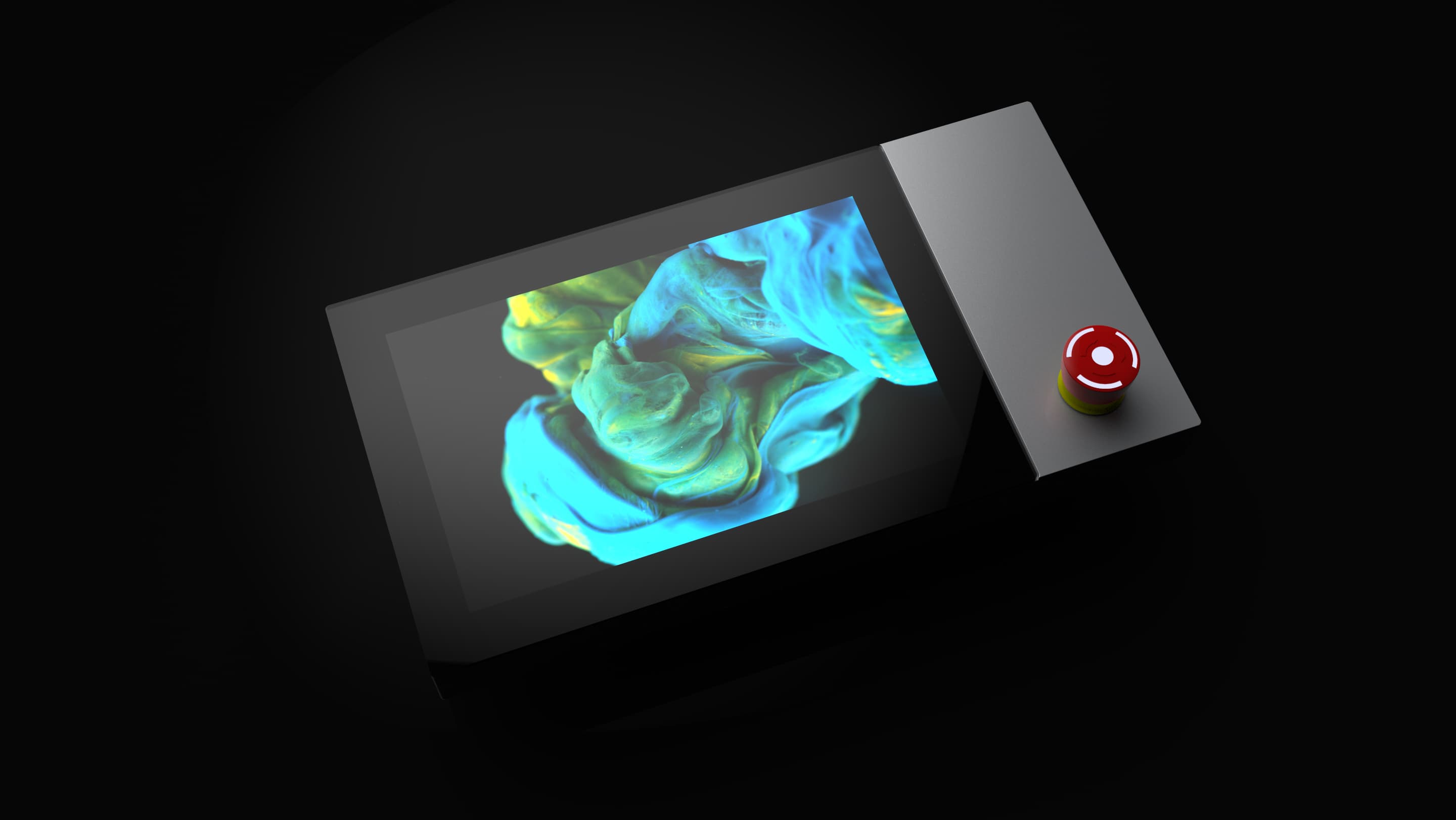

Human-Machine Interfaces (HMIs) have undergone significant advancements in recent years, with touch screen technology playing a pivotal role in this transformation. These modern interfaces have become essential in various sectors, including manufacturing, automotive, consumer electronics, and healthcare. They provide an intuitive and interactive means for users to control and monitor complex systems. This blog post explores the key features that make modern touch screen HMIs indispensable.

User-Friendly Interface

The hallmark of any effective HMI is its user-friendly interface. Modern touch screen HMIs prioritize ease of use through intuitive design elements. Clear icons and graphics help users navigate the system effortlessly, while responsive touch controls ensure quick and accurate interactions. Consistency in layout across different screens further aids users in learning and operating the system efficiently.

Customizability

Customizability is a significant feature of modern touch screen HMIs, allowing them to meet the specific needs of various users and applications. Users can personalize their experience by adjusting the size and position of controls, changing color schemes, and setting up shortcuts for frequently used functions. This adaptability ensures that the HMI can be tailored to different workflows and processes, enhancing overall productivity.

High-Resolution Displays

High-resolution displays are a cornerstone of modern touch screen HMIs, providing enhanced clarity and detail. These displays offer clear visuals that are crucial for monitoring complex systems and identifying issues quickly. The vivid colors available on high-resolution screens improve the readability of graphical elements, making the interface more visually appealing and effective.

Robust Performance

Performance is a critical aspect of modern touch screen HMIs. They are designed to offer fast processing speeds, ensuring that the interface responds promptly to user inputs and can handle complex tasks without lag. Additionally, modern HMIs are built to be reliable, capable of operating in various conditions, including harsh industrial environments, to ensure continuous operation without frequent breakdowns.

Advanced Connectivity

Connectivity is a vital feature that enables seamless communication between HMIs and other devices and systems. Modern HMIs typically include Ethernet and Wi-Fi connectivity, allowing them to connect to networks for data exchange and remote monitoring. They can also integrate with Internet of Things (IoT) devices, enabling advanced functionalities such as predictive maintenance and real-time data analytics.

Enhanced Security

With the increasing reliance on digital interfaces, security has become a paramount concern. Modern touch screen HMIs incorporate enhanced security features to protect sensitive data and ensure safe operation. User authentication mechanisms, such as password protection and biometric authentication, prevent unauthorized access. Additionally, data encryption ensures that sensitive information remains secure during transmission between the HMI and other systems.

Multitouch Capability

The multitouch capability of modern HMIs allows users to interact with the interface using multiple fingers simultaneously. This feature supports gesture controls like zooming, rotating, and swiping, making the interface more interactive and efficient. Multitouch capability also enables more complex inputs and commands, enhancing the overall efficiency of the interface.

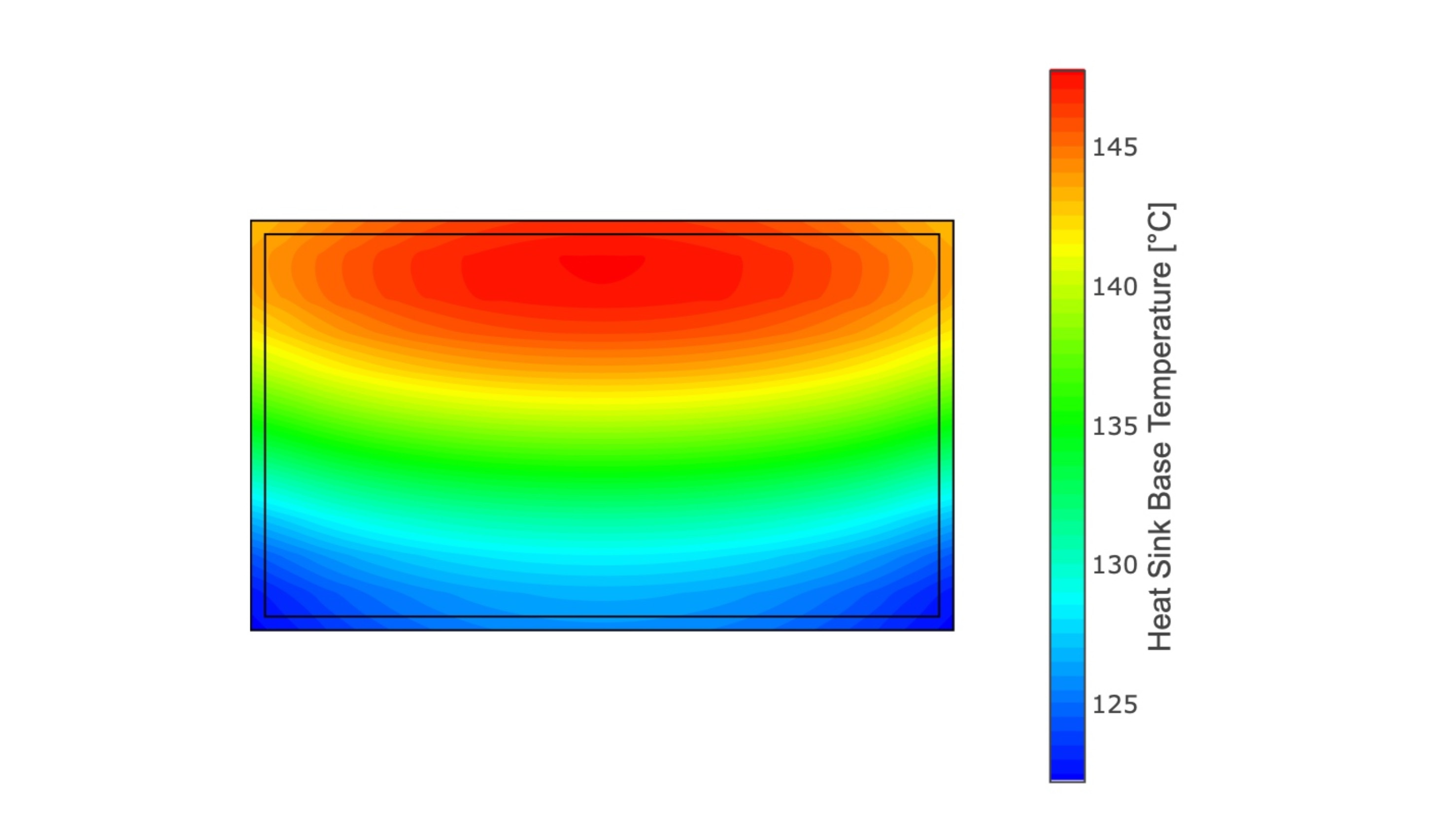

Real-Time Data Visualization

Real-time data visualization is a crucial feature of modern touch screen HMIs, essential for monitoring and decision-making. Dynamic graphs and charts display real-time data, helping users quickly understand trends and anomalies. Customizable dashboards allow users to monitor key performance indicators (KPIs) at a glance, providing a comprehensive view of system performance.

Voice and Gesture Control

In addition to touch interaction, many modern HMIs now incorporate voice and gesture control features. Voice commands enable users to perform tasks hands-free, which can be particularly useful in environments where touching the screen is impractical. Gesture recognition provides an alternative interaction method, enhancing accessibility and usability in various situations.

Scalability

Scalability is an essential feature for HMIs used in industrial and commercial applications. Modern touch screen HMIs are designed to scale according to the needs of the business. A modular design allows for easy expansion or upgrades as requirements change. Compatibility with various systems ensures that the HMI can integrate with different machines and systems, accommodating future growth and technological advancements.

Enhanced Diagnostics and Maintenance Tools

Modern touch screen HMIs are equipped with advanced diagnostics and maintenance tools to help users identify and resolve issues quickly. Built-in self-diagnostic tools can detect and report problems, reducing downtime and maintenance costs. Remote access capabilities allow technicians to diagnose and fix issues without being physically present, saving time and resources.

Environmental Adaptability

Environmental adaptability is a crucial feature for HMIs used in diverse and challenging conditions. HMIs designed for harsh environments are built to withstand extreme temperatures, moisture, dust, and vibrations. Automatic adjustment of screen brightness ensures visibility in various lighting conditions, from bright sunlight to dimly lit areas.

User Feedback and Analytics

Incorporating user feedback and analytics is vital for continuous improvement of the HMI. Usage analytics collect data on how users interact with the HMI, helping developers understand usage patterns and identify areas for improvement. Providing easy ways for users to give feedback ensures that their needs and suggestions are considered in future updates.

Compliance with Industry Standards

Compliance with industry standards ensures that HMIs meet the necessary safety, performance, and interoperability requirements. HMIs often need to be certified by relevant authorities to be used in specific industries, such as medical, automotive, or aerospace. Adherence to standard communication protocols ensures that HMIs can integrate seamlessly with other equipment and systems.

Future-Proofing

Future-proofing is an essential consideration in the design of modern touch screen HMIs to ensure longevity and relevance. HMIs with upgradeable software can incorporate new features and improvements over time without needing hardware replacement. Compatibility with emerging technologies, such as augmented reality (AR) and artificial intelligence (AI), ensures that the HMI remains useful and relevant in the future.

In conclusion, modern touch screen HMIs have revolutionized the way users interact with machines and systems. The essential features outlined above—user-friendly interfaces, customizability, high-resolution displays, robust performance, advanced connectivity, enhanced security, multitouch capability, real-time data visualization, voice and gesture control, scalability, advanced diagnostics and maintenance tools, environmental adaptability, user feedback and analytics, compliance with industry standards, and future-proofing—collectively contribute to the effectiveness and versatility of these interfaces. As technology continues to advance, HMIs will undoubtedly evolve further, incorporating new innovations to meet the ever-changing needs of various industries.