The Sensitivity of OLED Materials

OLED, or Organic Light-Emitting Diode, technology relies on organic materials that emit light when an electric current passes through them. These organic compounds are crucial for the exceptional display quality that OLEDs offer, including superior color accuracy and flexibility. However, these same organic materials are inherently sensitive to environmental conditions, particularly heat. High temperatures can cause the organic layers to degrade, leading to reduced brightness, color shifts, and even complete failure of the display over time.

Chemical Stability and Heat

The organic materials used in OLED displays are chemically complex and less stable at elevated temperatures. Heat accelerates the chemical reactions within these materials, causing them to break down more quickly. This degradation affects the emissive and conductive layers, diminishing the display’s performance. Understanding the chemical interactions and their response to heat is crucial for developing more robust OLED displays that can withstand harsh conditions.

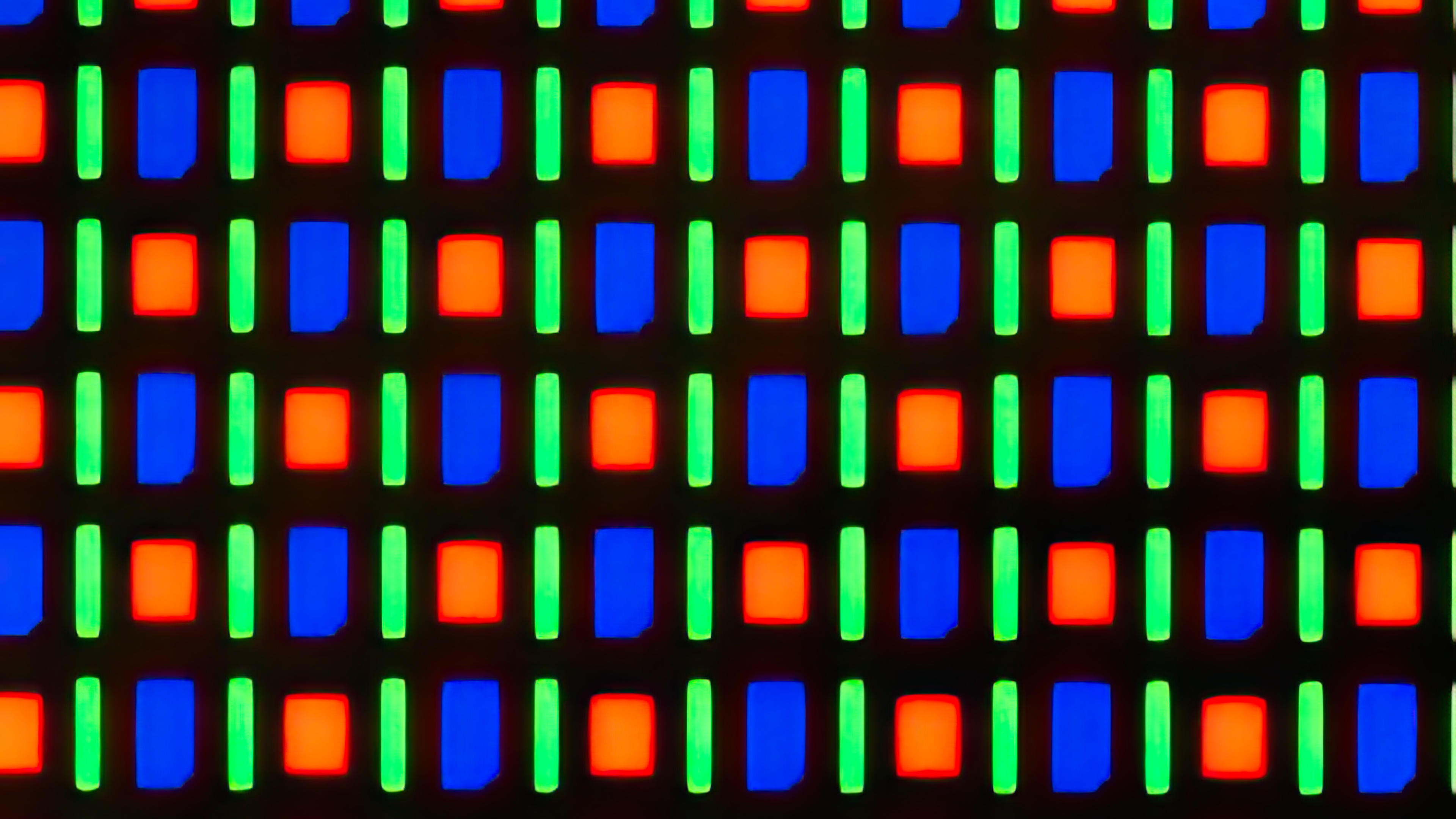

Electroluminescence and Material Degradation

Electroluminescence in OLEDs involves the movement of electrons and holes (positive charge carriers). When an electric current passes through the OLED material, these charge carriers recombine, and in the process, energy is released as light. Prolonged exposure to high currents can lead to the degradation of the material that facilitates this process. The organic compounds in OLED pixels are not as stable as the inorganic materials used in other types of displays, making them more susceptible to degradation over time, especially under high-energy operation. This fundamental property contributes to issues like OLED burn-in and reduced lifespan.

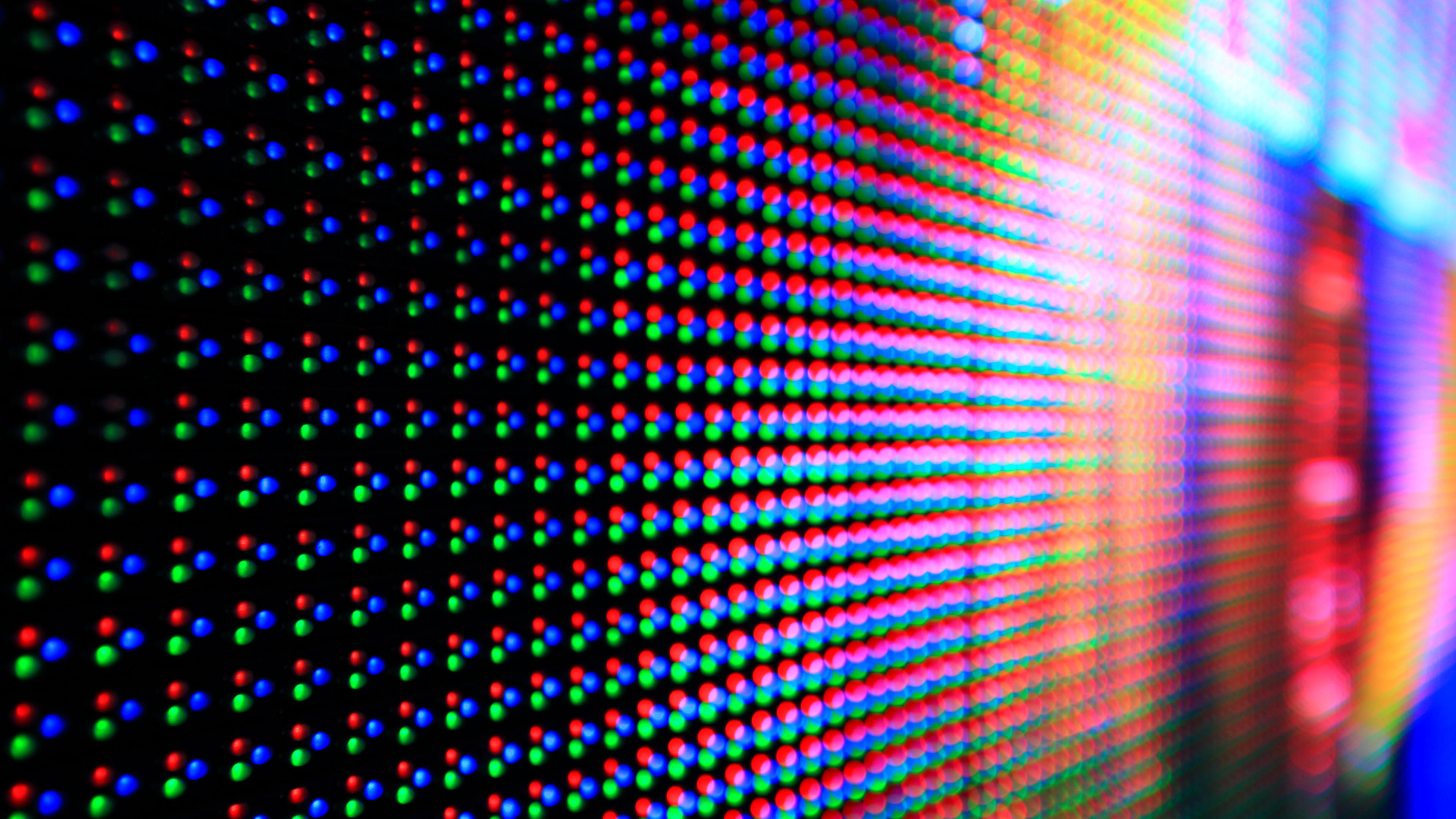

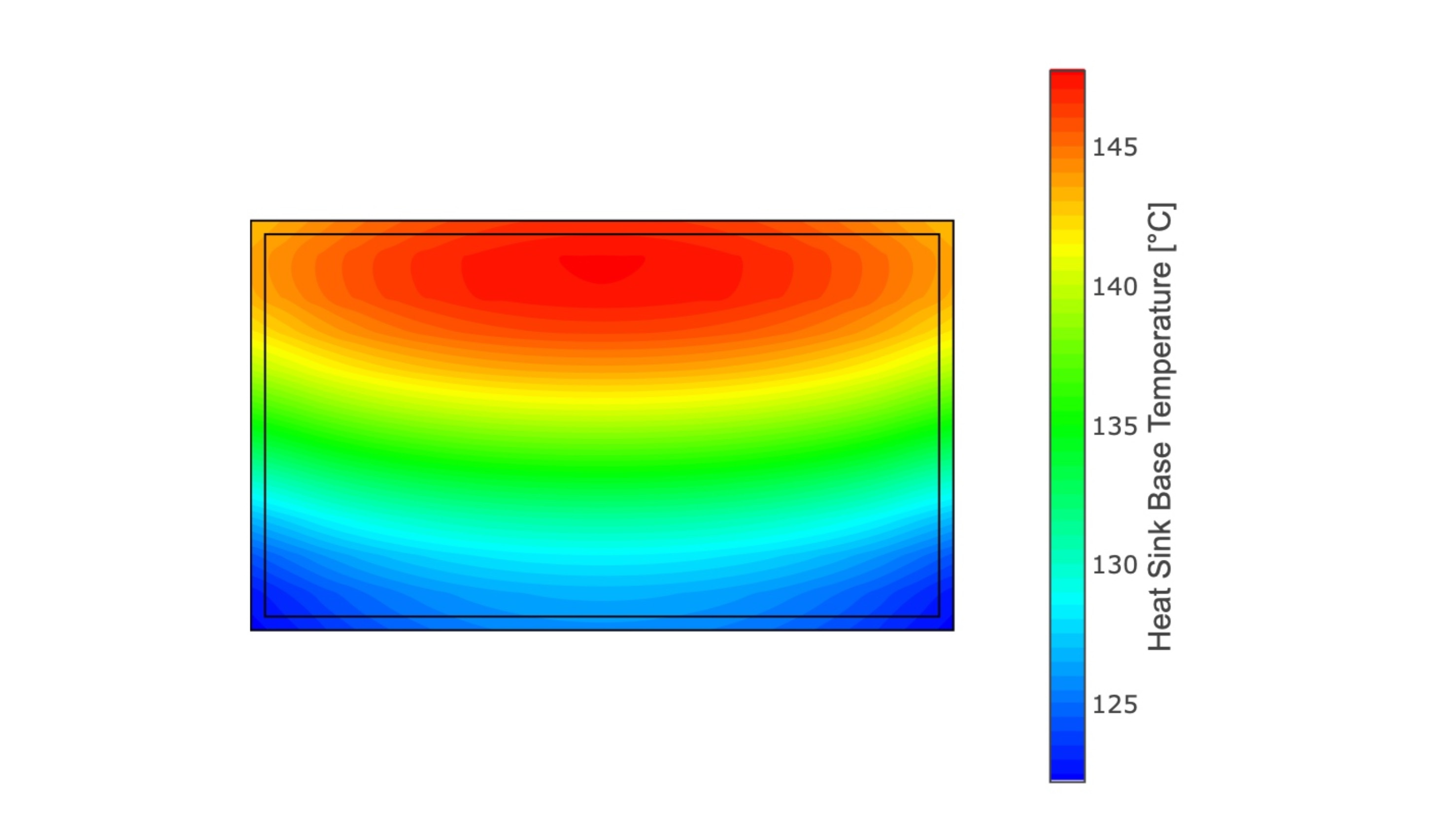

Thermal Management Challenges

Effective thermal management is essential for maintaining the performance and longevity of OLED displays. Unlike LCDs, which use backlighting, OLEDs generate light from each pixel. This self-emissive property means that heat is generated within the display itself, making it more challenging to dissipate. In high-heat environments, the internal temperature of the OLED display can rise rapidly, exacerbating the degradation process. Implementing advanced thermal management solutions is critical to mitigating these effects.

Impact on Performance and Lifespan

As OLED materials degrade under high heat, the performance and lifespan of the display are significantly impacted. The most noticeable effects include reduced brightness and color accuracy, which directly affect the user experience. Over time, image retention and burn-in issues can also arise, where static images leave permanent marks on the screen. These performance issues not only disappoint end-users but also increase warranty claims and product returns, affecting the bottom line.

Design Considerations for High-Heat Environments

Designing OLED displays for high-heat environments requires a multifaceted approach. Selecting materials with higher thermal stability, incorporating effective heat sinks and thermal interface materials, and optimizing the device architecture are all critical steps. Additionally, the design should consider the specific application and environment in which the display will be used. Whether it’s for automotive, industrial, or outdoor applications, tailored solutions are necessary to ensure reliability and performance.

Advances in OLED Technology

The OLED industry is continuously evolving, with ongoing research focused on improving the thermal stability and durability of displays. Innovations such as hybrid OLED structures, improved encapsulation techniques, and advanced materials are paving the way for more heat-resistant displays. Staying abreast of these developments is essential for companies looking to leverage OLED technology in challenging environments.

The Importance of Encapsulation

Encapsulation plays a crucial role in protecting OLED displays from environmental factors, including heat, moisture, and oxygen. Encapsulation involves sealing the OLED materials within protective layers that prevent degradation. High-quality encapsulation materials can significantly enhance the durability and performance of OLED displays in high-heat environments by providing a stable barrier against external elements.

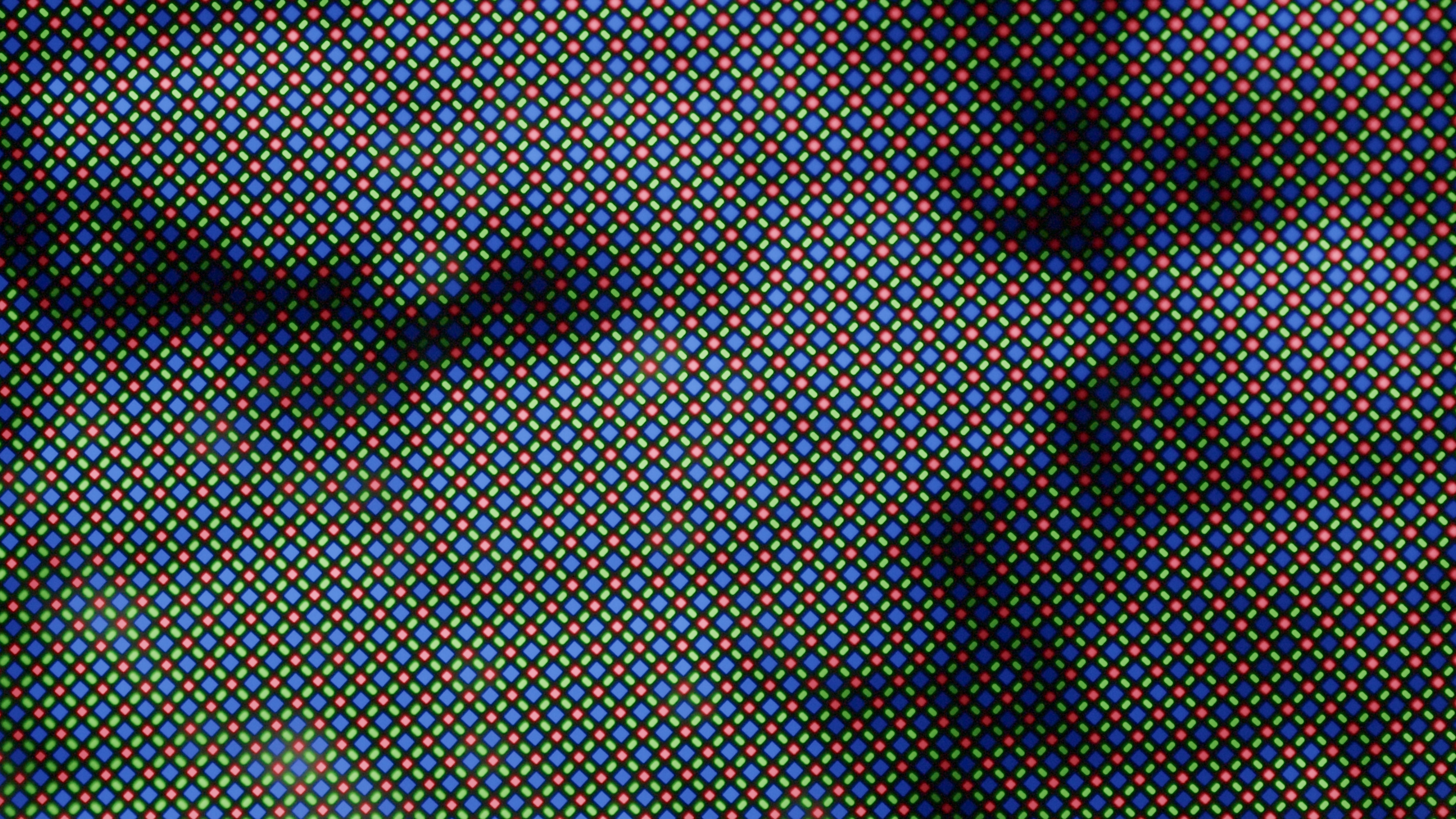

Barrier Materials for Enhanced Protection

Barrier materials are integral to the encapsulation process, providing a robust defense against heat-induced degradation. These materials are designed to be impermeable to moisture and oxygen, which are primary contributors to the degradation of organic materials in OLED displays. Advanced barrier materials, such as thin-film encapsulation (TFE) and multi-layer barriers, offer superior protection by combining multiple layers of inorganic and organic materials. These barriers not only protect the OLED from environmental factors but also help in maintaining the structural integrity of the display under thermal stress.

The Diffusion of O2 and H2O

In particular, the diffusion of oxygen (O2) and water vapor (H2O) through an encapsulation barrier generates defects or even failure in OLED displays. When O2 and H2O penetrate the barrier, they interact with the organic layers, causing oxidation and hydrolysis reactions. These reactions lead to the formation of non-emissive dark spots, reduced luminance, and color shifts. Over time, the accumulation of these defects can cause the display to fail entirely. Ensuring the barrier materials are effectively preventing the ingress of O2 and H2O is vital for the long-term reliability of OLED displays.

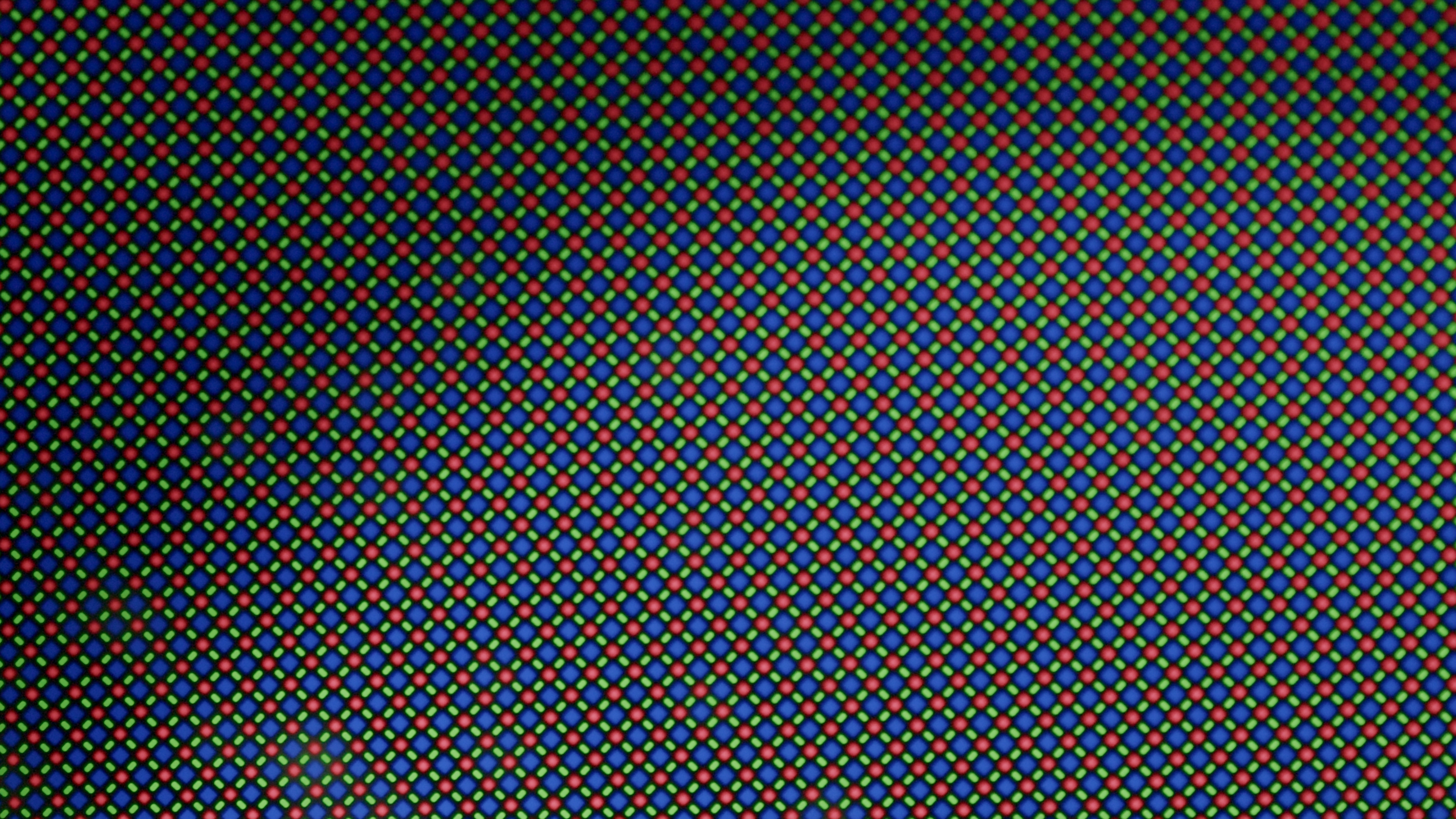

Challenges in Developing Flexible OLEDs

A significant challenge in developing flexible organic light-emitting diode (OLED) devices is protecting the OLED materials from damage caused by ambient moisture and oxygen. To ensure their longevity and performance, these devices need protective layers and encapsulants that have extremely low permeability to moisture and oxygen. Without such protection, the materials degrade rapidly, leading to device failure. Effective encapsulation is critical for maintaining the integrity and functionality of OLEDs in various applications. Researchers are continuously exploring advanced materials and techniques to create barriers that can provide this necessary protection, enabling the production of durable, high-quality flexible OLED devices. This ongoing innovation is key to advancing OLED technology and expanding its practical uses.

The Role of Testing and Validation

Comprehensive testing and validation are crucial for ensuring that OLED displays can withstand high-heat conditions. This includes accelerated life testing, thermal cycling, and environmental stress testing to simulate real-world conditions. By rigorously testing displays under extreme temperatures, manufacturers can identify potential failure points and implement design improvements to enhance durability.