When it comes to military-grade touchscreens, reliability and durability are always paramount. If, for example, touch displays are used for military vehicles, whether in standard size or large format, then ULTRA touchscreens (which are a resistive touch technology) are the first choice. This is because they are extremely resistant to water, chemicals, scratches and other damage due to the patented Glas film Glas structure.

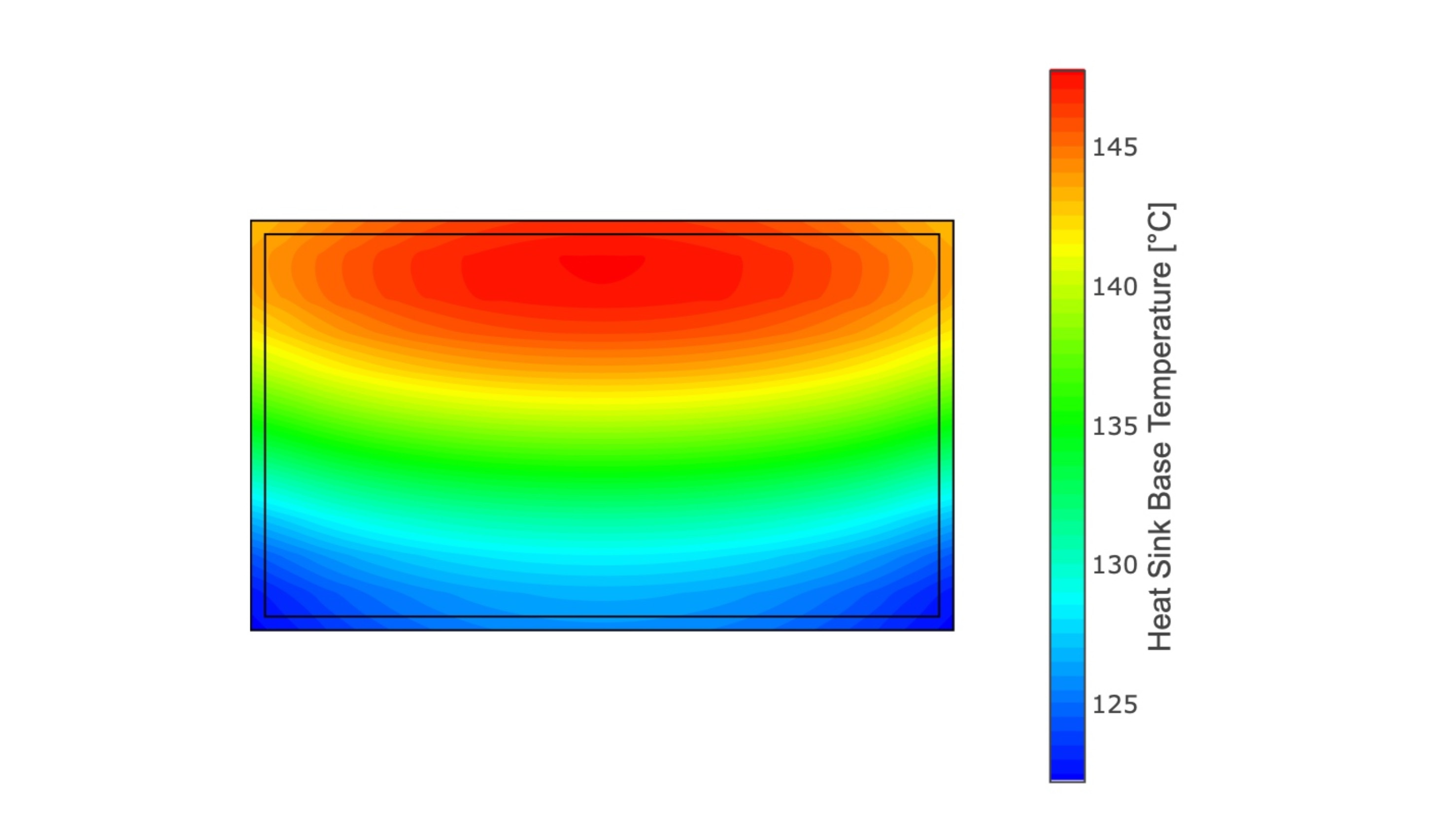

The service life of touchscreens at high temperatures and high humidity is also an important aspect, which requires, for example, the use of high-quality ITO materials (ITO = indium tin oxide). In addition, ITO-based touchscreen displays are characterized by excellent brightness and conductivity.

Displays for combat use

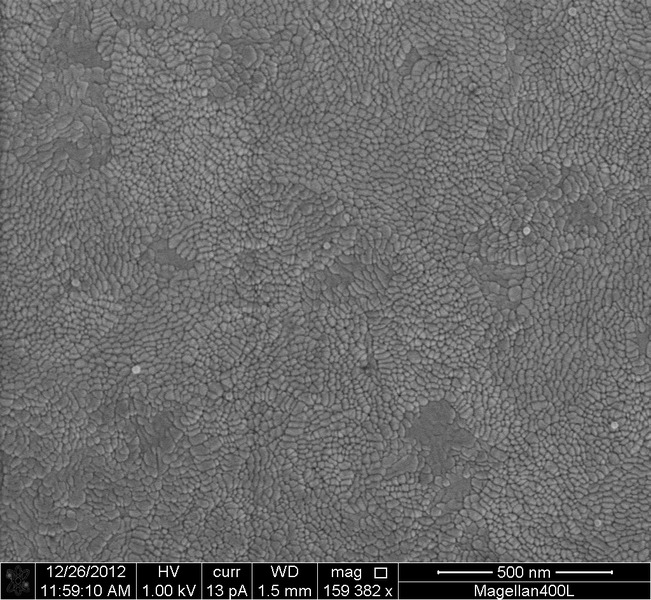

However, when it comes to portable displays for combat use, then soldiers prefer light and thin screens. Which are stable at the same time, consume little power but deliver consistent image quality. In this case, materials other than ITO are in demand. For example, silver nanowire (SNW = Silver nanowire). This massive switch from ITO to silver nanowire is due to the fact that ITO is no longer suitable, especially for flexible touch screens, because it cannot be bent as desired due to the Glas film Glas construction.

Advantages of SNW

Because silver is the most conductive material used to date, it is now also preferred for the creation of large-area touchscreens (e.g. 20" monitors). At this scale, high conductivity is an essential component of a fast response time, especially in multi-touch applications. By inserting film-based, transparent conductors into portable devices such as tablets or smartphones, it is possible to create thinner, lighter and more durable touchscreens. The higher transfer rate also ensures brighter displays and longer battery life.

If you would like to learn more about the design of a touchscreen to see where ITO is used, more information about the touchscreen design is available on our website.