LCDs (Liquid Crystal Displays), touch screens, solar cells and flexible displays use transparent, conductive, thin film electrodes. Indium tin oxide (ITO = indium tin oxide) is the most commonly used material for these applications.

Advantages and disadvantages of ITO

ITO is particularly conductive and at the same time has a high optical transparency. Despite the advantages mentioned, the use of ITO also has its downsides, because it is relatively brittle and not suitable for flexible substrates. In addition, it is expensive compared to alternative substitutes (e.g. metal mesh, graphene) and requires high temperatures during production.

However, the future of displays and other optical-electronic devices lies in the cost-effective mass production of suitable methods for flexible transparent electrodes. These manufacturing methods include, for example, "roll-to-roll" coatings or inkjet printing processes.

Substitute materials for ITO in the electronic field are conductive polymers and conductive nanostructures with a high aspect ratio. However, the low conductivity of polymeric transparent electrodes currently still severely limits their application. That is why there have been many research projects in this area during the last 10 years.

Advantages of Silver Nanowire (SNW)

In the future, suitable candidates for transparent electrode materials will also include nanowires, nanotubes and nanorods. Among these, carbon nanotubes in particular are being extensively researched. This is because they are flexible, have better conductivity similar to silver nanowires, and they are stable in areas of high/low humidity or temperature. Nevertheless, the properties of ITO (e.g. transmittance = 90% and sheet resistance < 100 Ω/sq) gearbeitet werden.

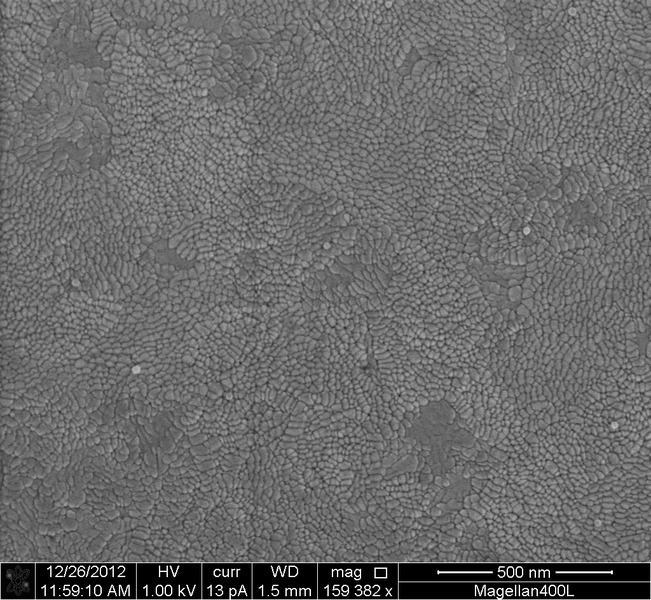

Dennoch sind Silber (Ag) Nanowire (NW) eine vielversprechende Alternative zu ITO. Sie haben nicht nur das Potenzial es zu ersetzen, sondern sogar zu übertreffen. Silber hat die höchste elektrische Leitfähigkeit (6,3 x 10 hoch 7 S/m) unter allen Metallen. Aufgrund dessen werden Ag Nanodrähte als sehr vielversprechende Kandidaten in der flexiblen Elektronik gehandelt.

Result

Currently, Silver Nanowires can be used as leaders in mass production compared to ITO, have excellent flexibility, high permeability. However, their use is still difficult in the production of silver nanowire ink.

If you would like to learn more about the design of a touchscreen to see where ITO is used, more information about the touchscreen design is available on our website.