Meat Processing Touch Screen

In the fast-paced, precision-driven world of food processing, the need for reliable, hygienic, and efficient technology solutions is critical. At Interelectronix, we grasp the unique challenges you face—balancing strict hygiene standards with the demands of harsh industrial environments. Our innovative food processing touch screens are designed to meet these stringent requirements, ensuring your operations remain productive and safe. Explore how our advanced touch screens can transform your workflow, offering unmatched durability and functionality tailored to your specific needs. Automotive grade components and extended Temperature Displays -30°C to +80°C (from -22°F to +176°F) and Touch Screens.

Who are our customers?

Our customers are global market and technology leading food and beverage equipment manufacturers passionate about Quality and Design. They operate in this demanding industry, where reliability and performance are essential. They do not accept the technological status quo and constantly push the limits to create outstanding products.

Durability

Impactinator® touch screens are engineered to endure the harsh physical demands of heavy-duty food processing operations. Built to withstand strong impacts from tools or machinery and resist constant vibrations from equipment like conveyors and mixers, these touch screens remain reliable over time. This robust construction reduces downtime and minimizes maintenance costs, allowing you to focus on productivity without worrying about equipment failure.

Environmental Resistance

Designed with superior resistance to environmental factors such as water, dust, oils, chemicals, and extreme temperatures, Impactinator® touch screens meet industry standards up to IP69K or Nema 4X for ingress protection. They prevent the penetration of contaminants that could compromise functionality. Whether operating in freezing cold storage rooms or hot baking areas, Impactinator® touch screens maintain optimal performance, ensuring consistent operation regardless of the environmental challenges your facility faces.

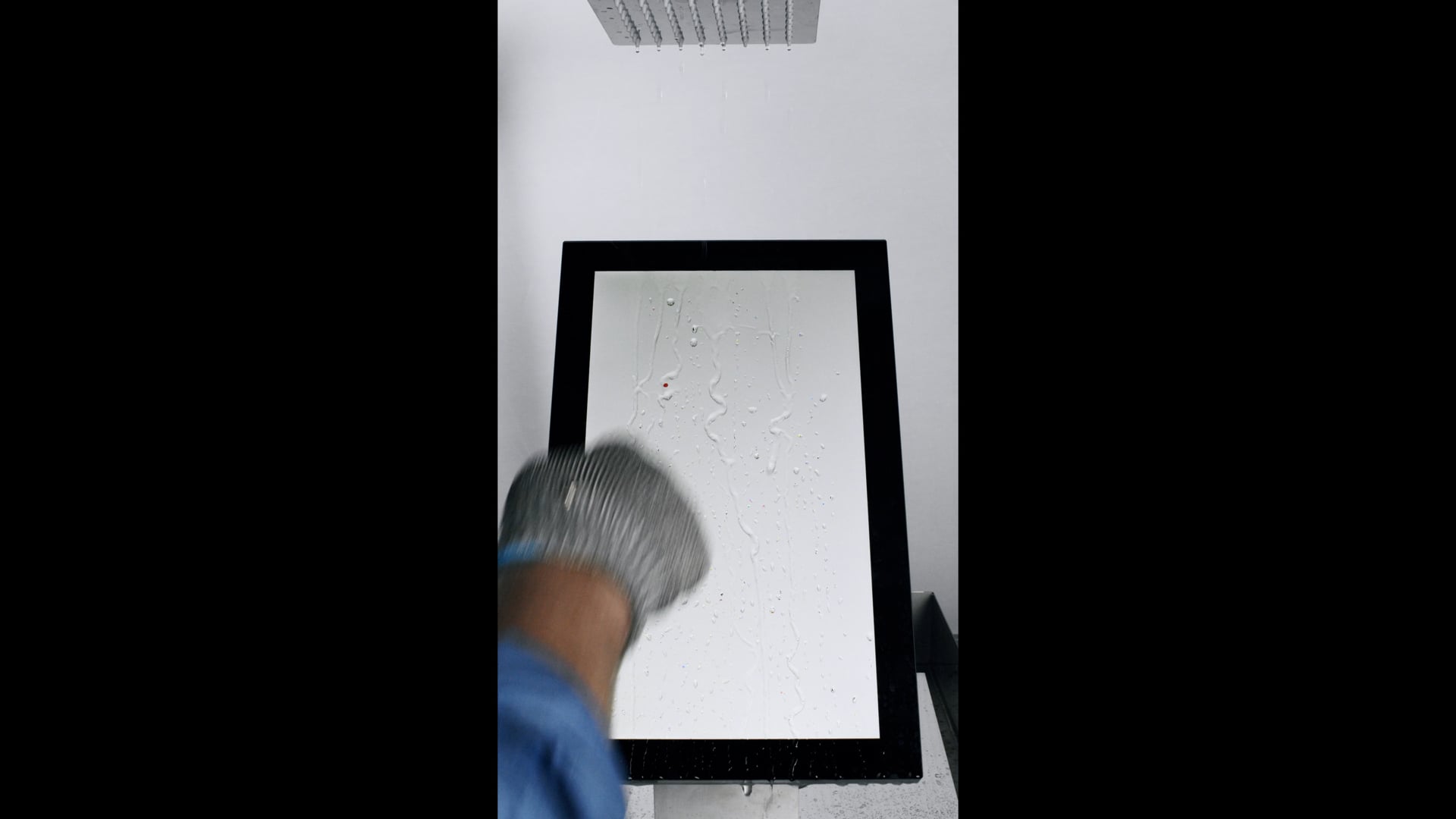

Easy Sanitization

Maintaining strict hygiene standards is crucial in food processing to prevent contamination. Impactinator® touch screens feature smooth, sealed surfaces that can endure frequent washdowns using high-pressure hoses and harsh cleaning agents like bleach or sanitizers. Their construction prevents the accumulation of bacteria and allows for thorough cleaning without damaging the screen or affecting its responsiveness. This supports stringent sanitation protocols and helps keep your facility compliant with health regulations.

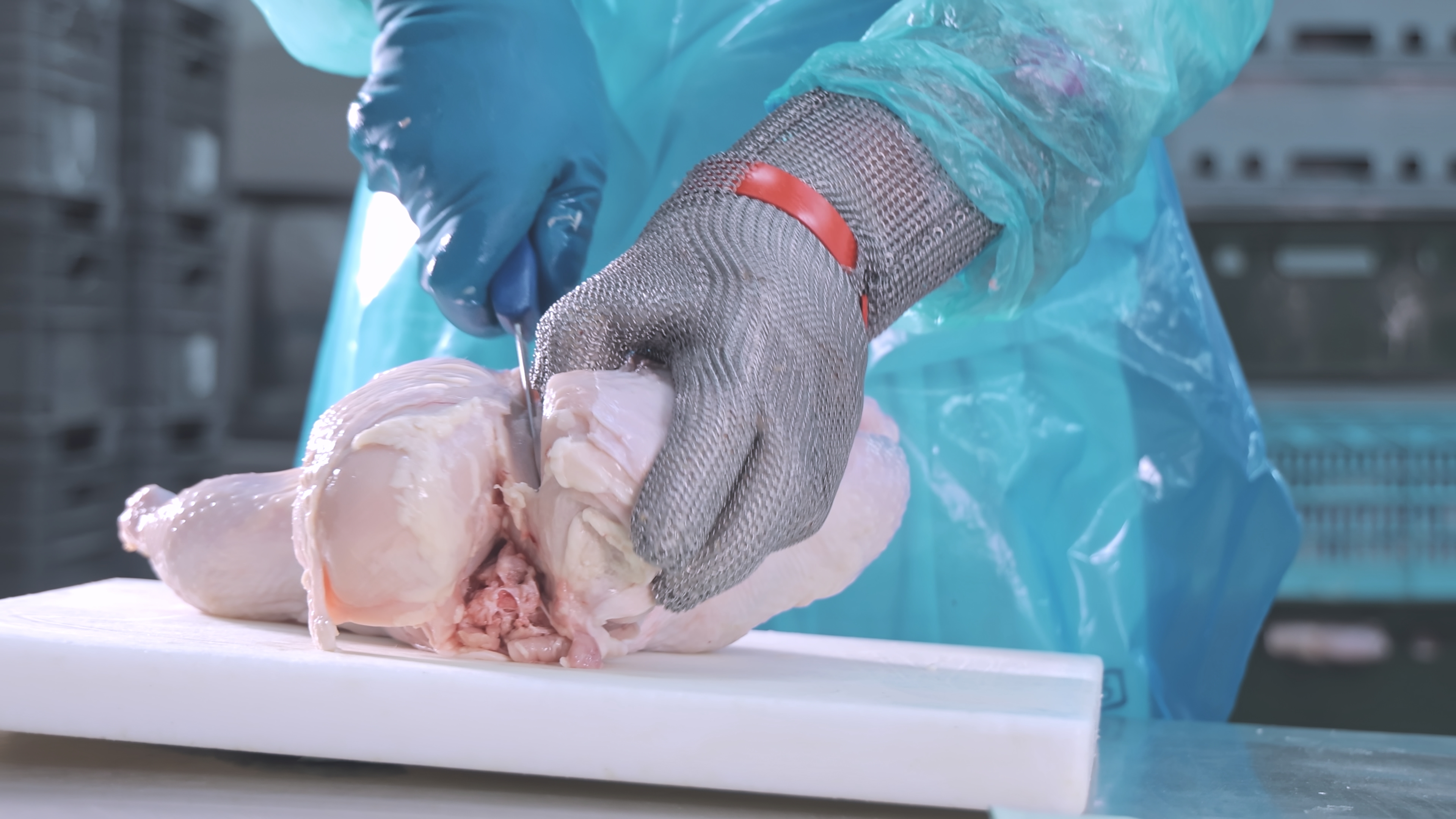

Operability with Gloves

In food processing environments, workers wear various types of gloves for safety, hygiene, and protection against extreme temperatures or sharp objects. Impactinator® PCAP touch screens are specifically designed to be responsive even when operators are wearing thick, insulated, or damp gloves. This feature enhances productivity and safety by allowing seamless interaction with equipment controls without the need to remove protective gear, keeping your operations running smoothly.

Touch screen User Interface in the Food Processing Industry

Touch-based technology is revolutionizing how operators interact with machinery in the food and beverage industry. The intuitive and straightforward usability of touch screens enhances machine handling, streamlining workflows, and boosting efficiency. Food processing companies must adhere to rigorous hygiene and safety regulations, impacting all equipment used in production.

Touchscreens with Special Security Standards

In the food processing industry, maintaining impeccable hygiene is non-negotiable. Touch screens deployed in this sector must comply with stringent safety standards while enduring the tough conditions typical of such environments. For example, meat processing plants require equipment robust enough to handle sharp objects, heavy impacts, and rigorous cleaning protocols.

Scratch Resistant Touch Screens

Meeting the demanding requirements of food processing necessitates touch monitors that are both robust and impact-resistant. In environments where knives and heavy boxes are commonplace, touch screens must withstand potential damage. Interelectronix’s Impactinator® technology ensures that our touch screens can endure strong impacts and sharp objects without compromising their functionality.

Shatterproof Glass

Our touch screens feature PCAP (Projected Capacitive) technology with a borosilicate glass surface, akin to laminated glass. This design ensures that even with deep scratches or significant impacts, no splinters are released, and the screen continues to function smoothly. This shatterproof quality is essential for food processing companies, where the presence of glass splinters in the production area would be unacceptable.

seafood processing

In seafood processing, Impactinator® projected capacitive touch screens are designed to resist saltwater corrosion and operate effectively in wet, cold conditions. Their sealed construction prevents moisture ingress, and they function reliably despite exposure to fish oils and scales. Glove-friendly touch capabilities enable seamless interaction, streamlining processes in challenging environments.

Reliable Touch Screen Operation with High Saline content Foods

Impactinator® PCAP touch screens are specifically engineered to function flawlessly in environments with 10% saline solutions, which are common in seafood processing. Unlike standard PCAP touch screens that often register false touches due to the high conductivity of saline concentrations, our touch screens maintain accurate and reliable touch recognition. This ensures that operators can interact with equipment seamlessly without interruptions or errors caused by saline interference. Impactinator® touch screens provide the precision and reliability needed to enhance efficiency and maintain high-quality standards in seafood processing facilities.

meat processing

Impactinator® touch screens are perfect for meat processing because they withstand harsh conditions like moisture, blood, and frequent sanitization. Their rugged design resists corrosion and damage from sharp tools, ensuring reliable operation. They are glove-friendly, allowing workers to interact without removing protective gear, enhancing efficiency and safety.

dairy processing

In dairy processing, Impactinator® touch screens excel due to their resistance to liquids, fats, and temperature fluctuations. Their easy-to-clean surfaces meet strict hygiene standards, preventing bacterial buildup. The screens maintain responsiveness even in cold or humid environments, making them ideal for monitoring and controlling dairy production processes.

poultry processing

For poultry processing, Impactinator® touch screens offer durability against feathers, fluids, and constant washdowns with harsh chemicals. They endure vibrations and impacts from heavy machinery, ensuring continuous operation. The screens’ operability with gloves allows workers to manage equipment safely, improving productivity while maintaining sanitation protocols.

Touch Screen Solution for High Heat Food Processing

We tackle the challenges of high-heat food processing with our Impactinator® touch screens, engineered for reliability under extreme temperatures. Partnering with Interelectronix, we ensure seamless performance that enhances efficiency, safety, and product quality. Explore how our solutions can transform your facility’s operations today.

Reliable Touchscreens No Downtime

The unbelievably durable glass surface of our Impactinator® touch screens prevents screen failure due to workplace accidents, ensuring uninterrupted production. Known for their high reliability and durability, Interelectronix touch screens eliminate downtime and support continuous industrial production. We understand that various branches of the food processing industry have different requirements, and our extensive experience allows us to provide custom touchscreen solutions.

Durable and Low Maintenance

Touch screens are crucial components of machines and industrial computers for data transmission across distributed systems. Whether installed permanently or used as portable devices, the reliability of these touch screens is vital for the industrial production chain. Interelectronix touch screens are designed for long-term use with minimal maintenance, ensuring they remain a dependable part of your operations.

Easy-to-Use Touchscreens

Our Impactinator® touch screens are both versatile and user-friendly. Using proprietary projected capacitive technology they offer universal handling. In food processing plants where gloves are essential for hygiene, our touch monitors respond efficiently to contact with gloves of any thickness, as well as with bare fingers. This flexibility enhances productivity by saving time and simplifying operations.

Why Interelectronix Food Processing Touch Screen

Interelectronix is committed to understanding and addressing the specific needs of the food processing industry. Our Impactinator® touch screens are not just robust and reliable; they are designed to ensure safety, hygiene, and efficiency in the most demanding environments while offering industry leading total cost of ownership. Whether you need a solution for a meat processing plant or any other food production area, we can provide customized touch screens that meet your specifications. Contact us today to discover how we can enhance your operations with our cutting-edge technology.