Quality control and sophisticated test procedures are often the key to the reliability and longevity of touchscreen products. Many manufacturers already offer technically and economically viable test procedures in this area. This article provides an overview of the common standards for quality control of touch screens.

5 Test Procedures for the Durability of Touch Screens: Test Methods and Quality Standards

In the rapidly evolving world of technology, the demand for durable and reliable touchscreens is higher than ever. As a product owner, ensuring the longevity of your touchscreens is not just about meeting customer expectations—it's about safeguarding your brand's reputation. Interelectronix understands the pressures you face, and we're here to clarify how to ensure your touchscreens stand the test of time. With years of experience in delivering high-quality touchscreen solutions, we've honed our expertise in test procedures that guarantee the durability and reliability of your products. This blog post will guide you through five critical test methods, providing you with the knowledge to make informed decisions and maintain the integrity of your touchscreens in any application.

Different Test Procedures Guarantee Durability

Touchscreens are integral to various applications, from consumer electronics to industrial machinery and medical devices. Each of these environments presents unique challenges that can affect the performance and lifespan of a touchscreen. Manufacturers use various test procedures to ensure that touchscreens can withstand these challenges. These procedures are designed to simulate real-world conditions and identify potential points of failure before the product reaches the market. In this section, we'll explore five key test procedures that are essential for assessing the durability of touchscreens: the Climate Change Test, HALT (Highly Accelerated Life Test), Shock and Vibration Tests, EMC (Electromagnetic Compatibility) Tests, and the Ball Drop Test.

Climate Change Test: Simulating Extreme Conditions

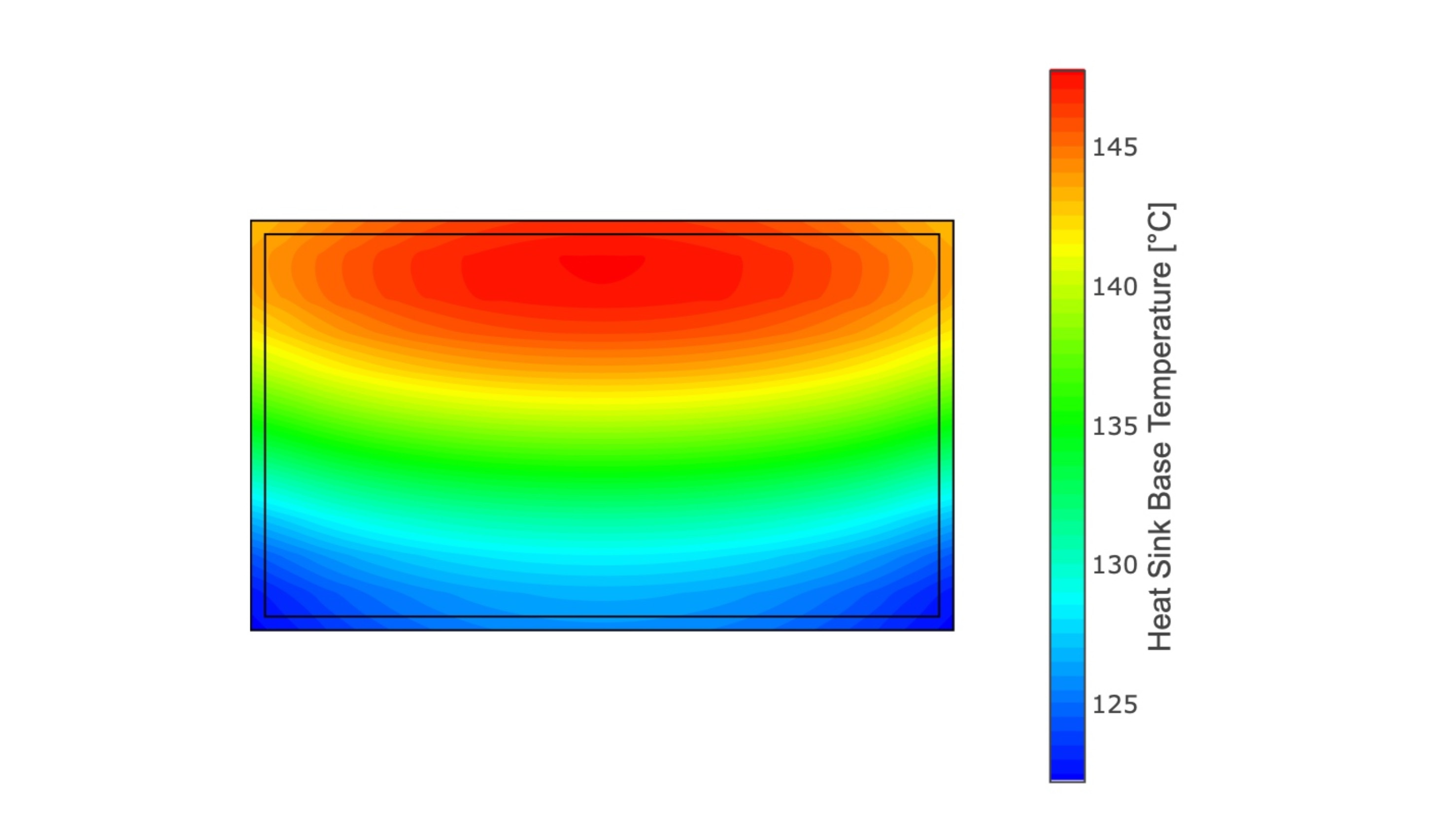

Touchscreens are often exposed to a wide range of environmental conditions, from winter's freezing cold to summer's scorching heat. The Climate Change Test is designed to assess how well a touchscreen can function under these extreme conditions. During this test, the touchscreen is exposed to a series of temperature cycles, ranging from -40°C to 80°C, depending on the specific application. This test helps manufacturers identify any weaknesses in the touchscreen's design that could lead to failures in extreme environments. By understanding how your product reacts to these conditions, you can ensure that it remains reliable, regardless of where it's used.

HALT: Accelerating the Aging Process

The Highly Accelerated Life Test, or HALT, is a crucial procedure for predicting the long-term durability of a touchscreen. In this test, the touchscreen is subjected to rapid cycles of extreme temperatures, high levels of vibration, and other stressors that it might encounter during its lifespan. The goal is to simulate years of use in just a few days. By identifying potential failure points early on, manufacturers can address these issues before the product is released to the market. HALT is particularly valuable for products that will be used in demanding environments, such as industrial machinery or aerospace applications. By incorporating HALT into your quality control process, you can significantly reduce the risk of product failures and ensure that your touchscreens maintain their performance over time.

Shock and Vibration Tests: Ensuring Resilience in Tough Environments

Touchscreens used in industrial, agricultural, or military applications are often subjected to harsh conditions, including sudden shocks and constant vibrations. Shock and Vibration Tests are designed to evaluate how well a touchscreen can withstand these forces. During these tests, the touchscreen is exposed to controlled shocks and vibrations that simulate real-world conditions, such as the jarring motion of heavy machinery or the impact of a rough landing in an aircraft. The results of these tests provide valuable insights into the mechanical robustness of the touchscreen and its ability to function reliably in challenging environments. For product owners, these tests are essential for ensuring that your touchscreens can handle the rigors of the environments in which they will be used.

EMC Tests: Protecting Against Electromagnetic Interference

Electromagnetic Compatibility (EMC) is a critical consideration for touchscreens used in sensitive environments, such as medical devices or military equipment. EMC Tests are designed to ensure that the touchscreen can operate reliably in the presence of electromagnetic interference (EMI) from other electronic devices. This is particularly important in environments where even a small malfunction could have serious consequences. EMC testing involves several methods, including galvanically coupled tests, coupled tests, inductively coupled tests, and radiation-coupled tests. Each method assesses the touchscreen's ability to function correctly in the presence of different types of electromagnetic interference. By passing these tests, a touchscreen can maintain its performance even in the most demanding environments.

Ball Drop Tests: Measuring Surface Robustness

In industrial environments, touchscreens are often subjected to accidental impacts, such as tools being dropped on them. The Ball Drop Test is designed to assess the durability of a touchscreen's surface by simulating such impacts. In this test, a steel ball of specific weight (typically 0.509 kg) is dropped from various heights onto the touchscreen to evaluate its resistance to cracking or other forms of damage. The Ball Drop Test is particularly valuable for products that will be used in environments where physical impacts are a common occurrence. By ensuring that your touchscreens can pass this test, you can offer your customers a product that is not only functional but also highly durable, even in the toughest conditions.

Why Interelectronix?

When it comes to the durability and reliability of touchscreens, Interelectronix is a name you can trust. Our extensive experience in the industry, coupled with our commitment to quality, ensures that your products are tested to the highest standards. We understand the challenges you face in bringing durable touchscreen products to market, and we are here to help you every step of the way. From Climate Change Tests to HALT, Shock and Vibration Tests, EMC Tests, and Ball Drop Tests, we offer a comprehensive suite of testing services designed to give you confidence in your product's performance. Don't leave your product's durability to chance—partner with Interelectronix and ensure that your touchscreens are built to last. Contact us today to learn more about our testing services and how we can help you deliver the best possible product to your customers.